Material is evenly fed into grinding chamber by quantitative feeding devices, strongly impacted by high-speed rotating grinding disc. At the same time, it is subjected to centrifugal force and collides with grinding ring gear and is subjected to various comprehensive forces such as shearing, friction and collision to finish grinding.

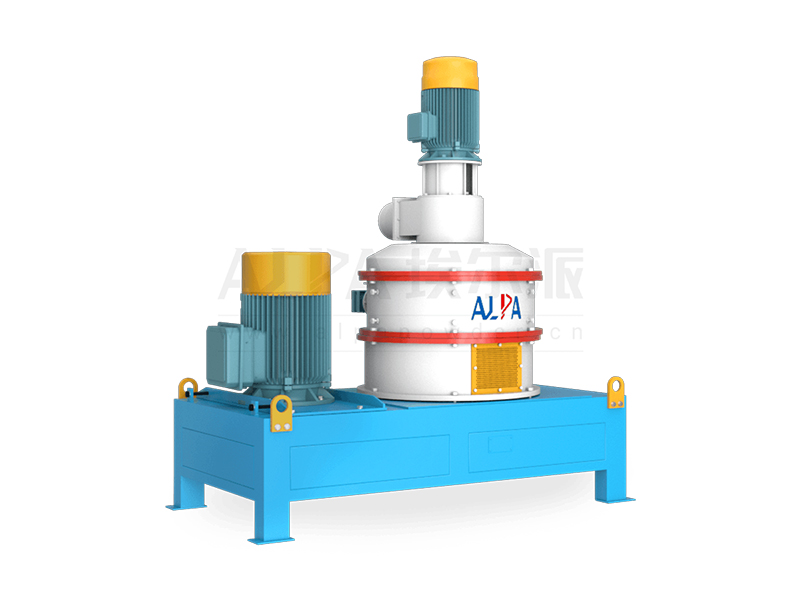

Product description

Adopting German technology, high-precision mechanical crusher, and continuous technological innovation and upgrading, suitable for 50-2500 mesh (300um-5um). The classic structure, the introduction of German technology, has a wide range of applications, derived from the traditional air classification mill (ACM), with more than 1,000 sets of applications. Widely used in non-metallic minerals (Mohs hardness below 5), chemicals, inorganic salts, medicine, food, pigments, dyes, pesticides, battery materials, minerals, refractory materials and other industries

Performance characteristics

Working principle

Material is evenly fed into grinding chamber by quantitative feeding devices, strongly impacted by high-speed rotating grinding disc. At the same time, it is subjected to centrifugal force and collides with grinding ring gear and is subjected to various comprehensive forces such as shearing, friction and collision to finish grinding. The milled material moves to classifying zone in the mill host with airflow. Rotating speed of classifier is control by inverter, separates the coarse and fine materials, the product that meet fineness requirement will be output and enters cyclone collector and bag filter with airflow, coarse powders return to milling zone for secondary grinding.

Technical parameter

Technical Parameters

| Parameter | CSM-280V | CSM-350V | CSM-510V | CSM-710V | CSM-1100V | CSM-1250V | |

| Power (kW) | Grinding Disc | 7.5 | 11~15 | 22~30 | 45~55 | 90~110 | 132~160 |

| Classifier Impeller | 1.5 | 2.2 | 4~5.5 | 7.5~11 | 15 | 18.5~22 | |

| Feeder | 0.55~1.1 | ||||||

| Rotate Speed(r/min) | Grinding Disc | 7500 | 6200 | 4200 | 2800 | 2100 | 1700 |

| Classifier Impeller | 500~4500 | 500~4000 | 400~3000 | 300~2500 | 250~2000 | 200~1600 | |

| Feeder | 20~100 | ||||||

| Max Air Flow (m3/h) | 700 | 900 | 3000 | 5400 | 10000 | 15000 | |

| Product Size(μm) | 5~300 | 10~300 | |||||

| Production Capacity(kg/h) | 2~100 | 10~400 | 15~600 | 30~1200 | 60~1500 | 300~3000 | |

TAGS